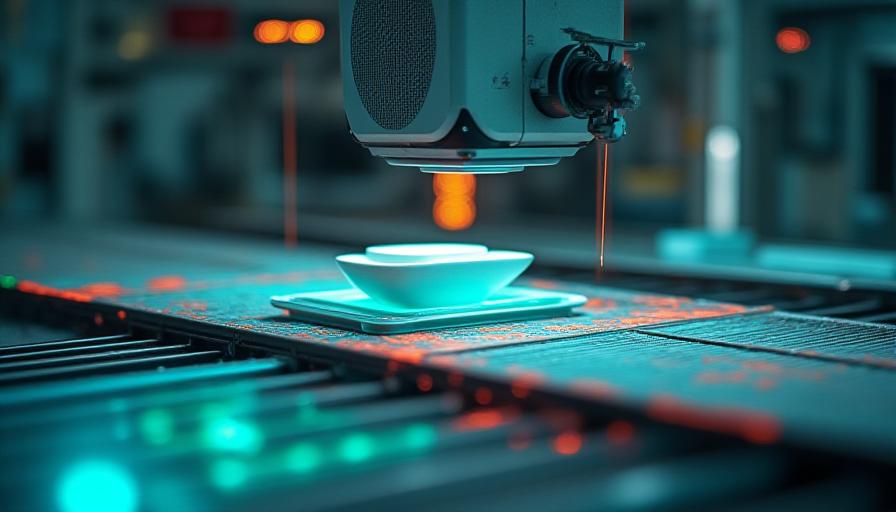

5 AI Trends Transforming Ceramic Manufacturing in 2025

Discover how machine learning, computer vision, and predictive analytics are revolutionizing traditional ceramic production methods. From automated inspection to intelligent material formulation, these technologies are setting new industry standards.

Read More →